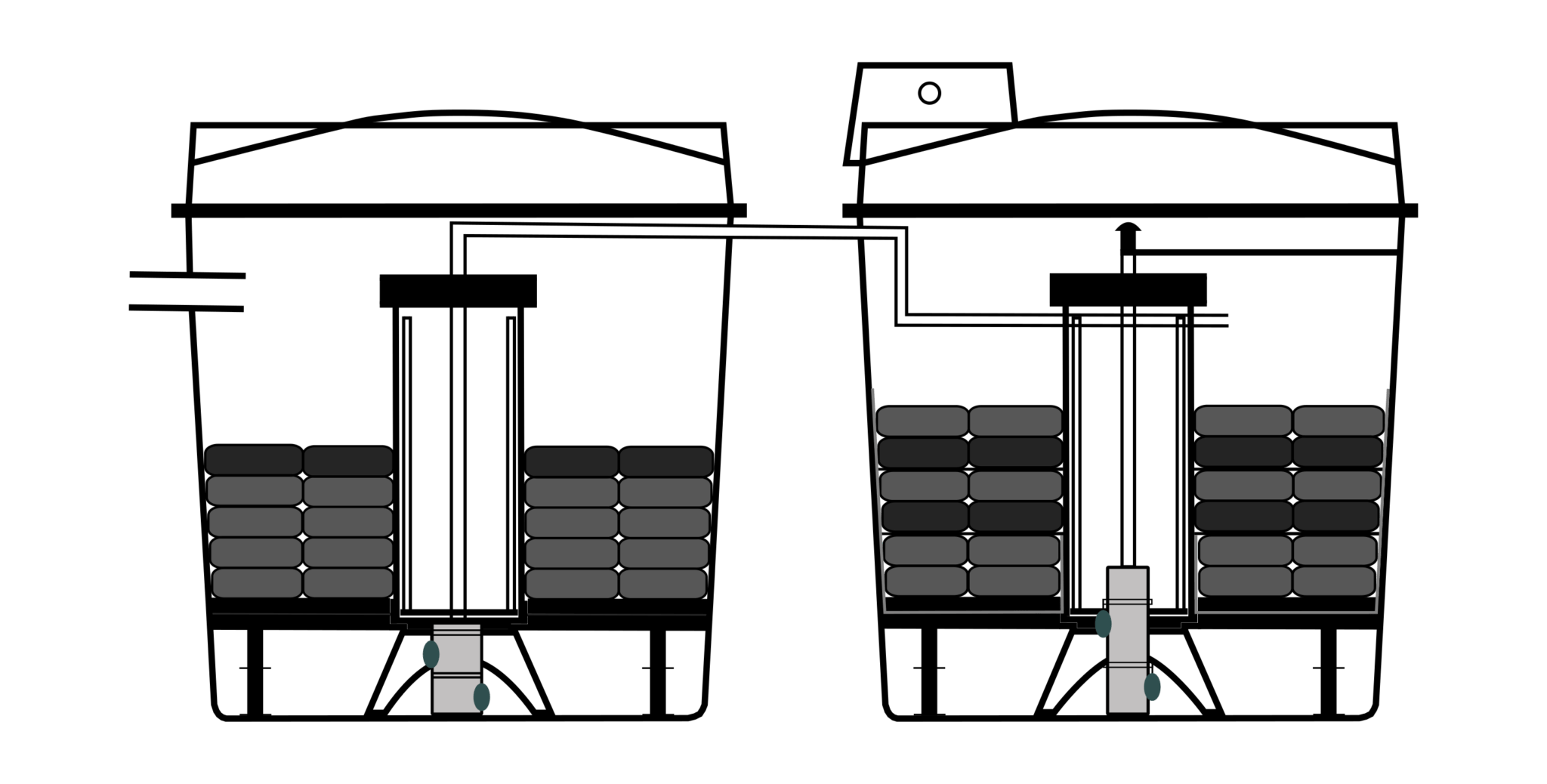

The BF8 filter process (Figure 1) is contained in two Reln injection moulded high grade polypropylene tanks in series.

The first module (BF2) receives all household wastewater via standard gravity drainage. The module contains 0.45m3 of plastic treatment media which acts as a roughing filter, reducing the solids and organic loading to the second module. Effluent percolates though the media layer and through a 3mm filter screen to the underdrain system. Larger solids are captured and broken down in the filter bed with smaller particles and soluble organic waste filtering through to the underdrain. A submersible recycle pump or air lift pump located in the bottom of the first tank distributes the primary treated effluent to the top of the second tank.

The second module is a standard Bio-Pod and consists of alternating layers of drainage elements and organic elements. All layers contain plastic trickling filter media contained in open-mesh bags. In the filter bed there is in excess of 1.3m3 of plastic filter media with a high porosity and a high specific surface area. The organic layers additionally contain coco peat, the fibrous structure of which significantly increases the available treatment surface. The layers are separated by a 3mm coarse HDPE mesh fabric.

The resulting filter bed mimics a natural soil habitat, containing a diverse ecosystem of micro and macro-organisms. These organisms aerobically treat the wastewater as it percolates through the bed. On commissioning, the filter is inoculated with 1 kg of tiger worms (Eisenia Fetida). These worms propagate and burrow through the filter bed, thereby keeping its structure open and porous. A small, quiet aquarium air pump is used to provide enhanced air flow to the bed imitating a gentle breeze, which ensures the optimal conditions for the waste processing ecosystem.

A geotextile filter layer separates the filter bed from the effluent storage sump. Its purpose being to remove the fine particles from the treated effluent. Effluent then drains into the central pump well, from where the now treated water is pumped to a land application system (e.g. drip irrigation) and returned safely to the environment and natural water cycle.

The BioPod, an “ecosystem in a tank”. From the outset the BioPod was engineered to be robust and built to last. It eliminates the mechanical complexity and problems of conventional wastewater systems, significantly reducing the running costs and without compromising on the quality of the treated effluent. With the BioPod the wastewater does not need to be separated into black and grey water, as it works with all standard plumbing and drainage configurations.

Vermifiltration is a powerhouse for efficient, odour-free wastewater treatment and Biolytix enhances this with additional aeration to achieve excellent waste breakdown to a Council-approved Secondary Treatment level.

Employing nature to do the work, the Biolytix BioPod is engineered to meet the needs of billions of hard-working organisms that treat your wastewater. Providing a stable environment, food as they would naturally find it, and an abundance of oxygen. With these ideal conditions the biolytic organisms concentrate on what they do best; continually processing solids waste for free.

When the raw sewage arrives in the Biolytix tank the Tiger Worms, Eisenia Fetida, get to work quickly. They are one of the strongest creatures for their bodyweight, and continually break up the sewage, creating millions of aerated channels. These are the ideal conditions for other organisms to move into, and together they complete the decomposition process. They quickly turn the sewage into humus. The wastewater is then cleansed as it trickles through the many channels in the humus.

The Biolytix worms have helped turn the problem – the solid sewage, into the solution - the humus to cleanse the wastewater.

And do feel free to go on holiday and the worms will hibernate. They eat little and don’t breed. Then when you are back they rejuvenate, replenishing themselves at the rate they are needed. They can also handle extended family and extra visitors – the worms party as well, making the most of the banquet!

In this middle of the treated wastewater compartment is the disposal pump which operates on-demand (typically less than 30 minutes per day) to dispenses treated effluent from the BioPod out to the irrigation system. The disposal pump is powerful enough to pump more than 50m vertically which allows even the most topographically challenging sites to be irrigated.

Enjoy the peace of your backyard with a system that blends in harmoniously, with no septic smell and no loud pump noise.

A major advantage of the BioPod is that it is not reliant on complex or expensive machinery to run. It has a minute, whisper quiet but robust, low energy and low volume air pump which ensures the ambient air in the BioPod is constantly refreshed providing an abundance of available oxygen supply for the aerobic organisms that do all the work in the filter. It blower only consumes 0.12 kWhours per day (approximately 3 cents per day) which is extremely low compared to other conventional aerated wastewater systems, which typically consume 10 to 20 times this. In addition to this, the air pump is whisper quiet. We have field and factory tested installed BioPod and recorded maximum noise of less than 40dB from a distance of just 1m. By comparison, the blowers used on aerated wastewater systems can be very noisy and can operate 24 hours a day.

The BioPod is extremely reliable but has an audible and visual alarm installed to let you know of any irregularities within the system.